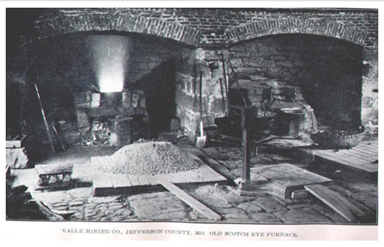

The Valles Mines Smelter was one of 5 smelters just in the immediate area.

This smelter chimney has recently fallen down in part. The Furnace Tender

lived right next door to it.

Smelters were a commonplace in the Missouri Lead Belt and melting ore required to get a marketable product,

usually an ingot, out of a pile of

raw galena ore. So much ore was taken out of the Lead Belt that they built a special road for the area, first the Selma

Road for ox carts, and later a railroad, the M.R.B.T. (Mississippi River and Bonne Terre) which ran for years straight to the

Herculaneum smelter, the biggest in the area.

Doe Run, one of the last mining company's left in

Missouri as of 2011 was

building a new one there. They even solved the emissions question that plagued lead smelting.

"In March 2010 Doe Run announced that it had developed a new lead production process that virtually eliminates

lead air emissions and sulfur dioxide emissions by replacing traditional high-temperature furnace smelting with

a new, contained wet chemical process. The technology uses a chemical solution to selectively dissolve lead into

solution. An electrical charge is applied to the solution to attract lead ions to a metal plate.

The process also eliminates the production of slag, a granular byproduct that has to be stored in permitted storage areas. "

Unfortunately, while the market for lead has recently risen to an historic high of $1

a pound, this has done little to revive an industry so much a part of Missouri's history. Doe Run eventually announced it

would not be smelting lead ore concentrates in Herculaneum after 2013. With Chinese mining companies buying old Missouri

lead mines, it raises the question, "Where will they smelt their ore?" Is the Lead Belt dead?

The old smelters were not environmentally friendly and left a residue that lasts for a long time, even centuries.

Missouri's Lead Belt is littered with hundreds of these open-air smokestack sites. Valles Mines' smelter was no exception and

the chimney pictured did not get high marks on its residue test.

Recently the EPA began cleanup of nearby residential areas but as Valles Mines has few residents, the Superfund started work

in highly populated areas elsewhere. Meanwhile, instead of ore mining, we "phytomine".

In phytomining, the trees absorb these harmful metallic residues. They "can be recovered from the phytoremediation

process of phytomining....The recovery of metals from metal contaminated sites, using high biomass producing plants is known

as phytomining..." "Phytoremediation is defined by UNEP (2012a,b) as the use of living green plants for in situ

removal, degradation, and containment of contaminants in soils, surface waters, and groundwater."

This may take a while but it is under way.